2022-09-12

New materials for more shaft safety

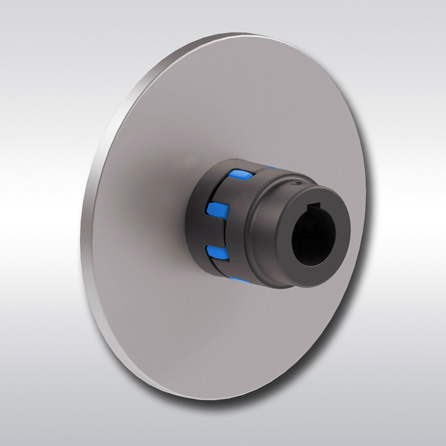

RINGSPANN now supplies REK jaw couplings with high-temperature spiders

RINGSPANN is driving forward the expansion of its portfolio of functional machine elements for industrial drive technology with a large number of small and large innovations. The internationally active one-stop supplier is becoming particularly dynamic in the field of shaft couplings. While it has recently made a name for itself here with a new type of hinge joint coupling, the company is now presenting new spiders made of more temperature-resistant materials for the torsionally flexible jaw couplings of its REK…DCO series and its Smart Solution REK…DCS. This gives designers the opportunity to make compensation of radial, axial and angular misalignment in drive shafts even safer.

Bad Homburg, September 2022. – „ When it comes to the vibration-damping and compensation of dynamic radial, axial and angular offsets in drive trains, the torsionally flexible jaw couplings of the REK...DCO series from RINGSPANN are among the preferred premium solutions for many well-known machine and plant manufacturers. These maintenance-free and fail-safe shaft couplings score with a progressive torsion spring characteristic and are characterized by their compact design and excellent running properties, among other things. In particular, the vibration-damping transmission of torques in the drive shafts of crane chassis, machine tools, belt conveyor, pumps and fans is part of their large areas of application. In order to give designers and developers in these industries even more leeway for the realization of safe, heavy-duty and high-performance shaft connections, RINGSPANN is now supplying its REK jaw couplings with new spiders made of elastomer materials with increased temperature resistance. In concrete terms, this means: the jaw couplings in the REK...DCO series can now be equipped in all ten sizes with three different spiders with the hardness 92 Shore-A, 98 Shore-A and 65 Shore-D, which allow operating temperatures of up to 120°. RINGSPANN Product Manager Martin Schneweis explains what this means for the practical use of the couplings: “Our new spider materials are suitable for operating temperatures of up to +120°C and offer up to 13 percent higher strength than the previously used plastics. As a result, in the average temperature range from 30°C to 80°C, the nominal torques of the jaw coupling increase considerably compared to the previous versions. Even at room temperature, the new materials allow higher torques than their predecessors thanks to their higher hardness.“

Higher safety level achievable

By equipping the REK jaw couplings with the new spider materials, RINGSPANN enables plant designers and machine manufacturers to raise their drive trains to a higher level of safety. Incidentally, the same applies to those customers who use the Smart Solution REK…DCS, a ready-to-install combination solution of REK coupling with brake disc, in their applications. Replacing older versions is also simplified by the fact that the size of the couplings compared to the predecessors does not change in all this. “For reasons of customer orientation and service quality, however, we will continue to provide the spider materials offered so far in minimum quantities on a project- and customer-related basis”, stresses Martin Schneweis. The new spiders remain visually distinguishable due to their colouring: the TU 92 Shore-A variant is gray, TU 98 Shore-A is blue and TU 65 Shore-D is white. The older versions are red and yellow.

More possibilities for designers

The introduction of new, more temperature-resistant spider materials for the jaw couplings of the REK...DCO series and the Smart Solution REK...DCS is one of numerous detailed innovations that RINGSPANN has recently implemented in this area of torsionally flexible shaft connections. In addition to the already existing range, it once again expands the possibilities of customer- and application-specific adaptation of this type of coupling many times over. “As a result, customers can no longer only choose from ten sizes with different bore diameters as well as hubs made of steel, cast iron or aluminium on the input and output side, but now also from three elastomer spiders with different degrees of hardness”, says Martin Schneweis.

RINGSPANN's current complete range of shaft couplings extends over 23 series, representing almost all types currently required in mechanical and plant engineering. Designers, product developers and engineers thus have a wealth of quality solutions for the implementation of rigid, torsionally rigid or flexible connections between shafts, gearboxes, motors and machines. A large part of the portfolio is now available in the company’s web shop, where catalogues, data sheets, operating instructions and the 3D CAD data are also available for download. ms