2022-10-18

Knowing what's going on inside

RINGSPANN presents new condition monitoring system for backstops

From now on, RINGSPANN is also offering a software- and sensor-supported condition monitoring system with WWW connection for its low speed backstops. It enables comprehensive real-time control of all function-relevant events inside the freewheels. In particular, this gives operators and maintainers of bulk material plants the opportunity to proactively monitor important performance parameters of the backstops in the drive systems of their conveyor systems. This increases operational reliability and reduces maintenance costs.

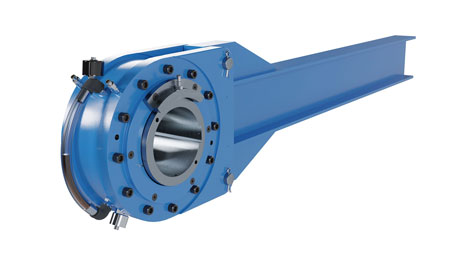

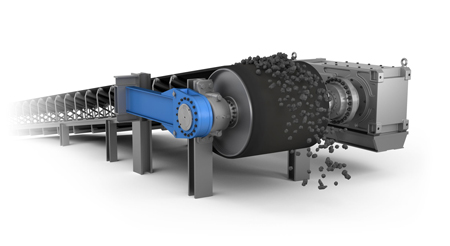

Bad Homburg, October 2022. – The low speed backstops of the FRHD, FRHN and FRSC series are among the freewheels of the RINGSPANN portfolio that the company provides as a ready-to-install complete solution with torque arm for mounting on the shafts of conveyor systems and output shafts of gearboxes. They are used worldwide as components of operational safety in conveyor belts, bucket elevators, screw conveyors, elevators and pumps for bulk materials, recycling and coal and steel technology. "On the one hand, they prevent serious accidents due to unexpected backward running of the systems, but on the other hand, they enable the drive units to be decoupled at any time in a controlled manner – when the conveyor belts or bucket elevators are fully loaded", explains Thomas Heubach, head of RINGPANN’s freewheel division. These backstops are characterized by a number of noteworthy quality features. For example, the high-quality Taconite seals, which give them an extremely high resistance to dirt, and the exceptionally high nominal torques of up to 1,215,000 Nm.

Condition monitoring at 4.0 level

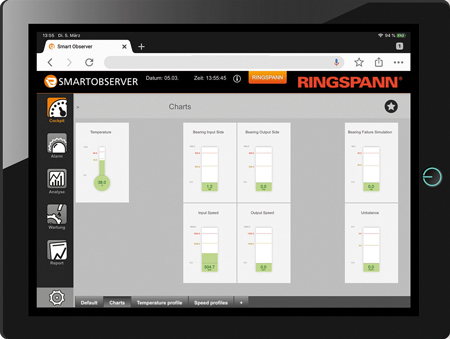

RINGSPANN now offers a sensor- and software-supported operating status monitoring system at Industry 4.0 level for all three series of its low speed backstops. Both the operators of the conveyor systems and their MRO and service teams thus receive a modern instrument of condition monitoring that can be used in the context of preventive maintenance. The system solution consists of a vibration sensor for monitoring bearings and imbalances, a speed sensor and an oil moisture sensor with temperature sensor and all the diagnostic electronics required for further analysis. The user can (remotely) retrieve all measurement data from the sensors in real time via an Ethernet interface and evaluate them with the Smartobserver software, which is also part of the system scope.

With the new operating status monitoring, RINGSPANN covers all aspects that are relevant for the sustainable, efficient and cost-effective operation of its low speed backstops. In the sense of preventive or predictive maintenance, the system informs, for example, about the possibility of unexpectedly high heating of the backstop – and opens up the possibility of planning maintenance sensibly. This is an important contribution to increasing plant availability. Expensive consequential damage can be avoided and the repair effort can be reduced, because the system detects irregularities at an early stage and the affected systems can then be shut down in a controlled and safe manner. In addition, the system supports the identification and analysis of sources of interference, from which targeted measures for process optimization can be derived. The effectiveness of repairs carried out can also be checked. And the data obtained from the operating condition monitoring can also be used to provide evidence in the event of warranty issues.

Remote scrutiny

Thanks to the Ethernet interface and data transfer via WWW, the control station personnel of the plant operator, the quality manager or the maintenance technician can follow the MRO-relevant events in the backstop in real time. For this purpose, the Smartobserver software provides all functions in the RINGSPANN operating status monitoring system: world and country maps show the user the locations of the freewheels, various traffic light symbols mark the position and function of the sensors, and diagrams provide information about vibrations and vibration limits. A warning symbol lights up if a fault is diagnosed inside the backstop or a critical condition is reached. If required, the user can also send the analysis and monitoring data for evaluation directly to the freewheel specialists of the international manufacturer of high-quality components for industrial drive technology.

With the new operating status monitoring for its low speed backstops, RINGSPANN is expanding the range of its Industry 4.0 solutions for condition monitoring. Such a system has also been available for the housing freewheels of the FH series for about two years now. These are overrunning freewheels with nominal torques from 1,356 to 81,000 Nm, which are used, for example, as automatic overrunning clutches in powertrains with multiple fast-rotating engines or turbines. "I am pretty sure that we will gradually expand the topics of condition monitoring and predictive maintenance to other series in our freewheel portfolio," says Thomas Heubach. ms

Market leader with growing one-stop shop

Auf dem Gebiet der Freiläufe gilt RINGSPANN als internationaler Marktführer. Das Unternehmen beliefert weltweit etwa 6.000 Kunden mit diesen Maschinenelementen zur Realisierung von Rücklaufsperren, Überhol- und Vorschubfreiläufen in der Antriebstechnik. Prinzipiell bestehen Freiläufe aus einem inneren und einem äußeren Ring mit zwischenliegenden Klemmelementen. In der einen Drehrichtung besteht keine Verbindung zwischen Innen- und Außenring (Leerlauf); in der Gegenrichtung hingegen sorgen die Klemmelemente für eine kraftschlüssige Verbindung zwischen Innen- und Außenring (Mitnahmebetrieb). Über seine zahlreichen Freilauf-Baureihen hinaus bietet RINGSPANN in seinem Webshop eine große Auswahl an Welle-Nabe-Verbindungen, Überlastkupplungen, Wellenkupplungen, Industriebremsen sowie Präzisions-Spannzeugen und Fernbetätigungen an. Sowohl der Webshop als auch das Gesamtangebot werden ständig ergänzt und erweitert.